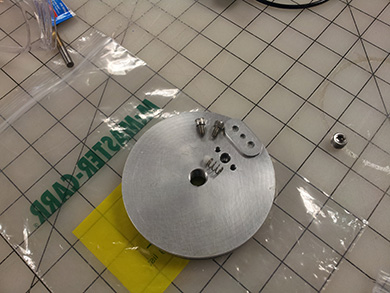

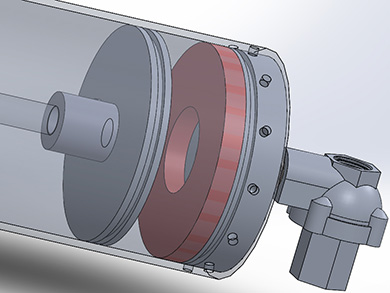

Large Bore Cannon

There’s one last know problem. I’m not sure how to attach the rubber bumper to the cannon back.

There’s one last know problem. I’m not sure how to attach the rubber bumper to the cannon back.I’m hesitant to use adhesive, because I don’t want the joint to degrade if the cannon sits in storage for years. I’m going for heirloom quality here.

I haven’t been able to think of a better method, so I’m going to give adhesive a shot. I feel like maybe I’ve just been using the wrong adhesives in the past, so I called up Loctite and asked what they recommend for this. I was actually able to talk to a person about it which was nice. The woman I talked to recommended #380 so I’ll try that. Hopefully I’ll get a pretty permanent bond.

I also bought a razor saw for 10 bucks on amazon to hopefully make cutting the rubber bumper easier. I tried with a razor blade previously, and it was just not having it.

I also bought a razor saw for 10 bucks on amazon to hopefully make cutting the rubber bumper easier. I tried with a razor blade previously, and it was just not having it.

2. I cut out and attached the bumper.

2. I cut out and attached the bumper.The cutting out part turned out to be very difficult. The rubber I used is soft, but tough and scissor resistant. I eventually got it cut, but the edge looked awful. It was usable, but I wanted to do better.

I tried a bandsaw (it just gummed up immediately). I tried lubricating the blade and sandwiching the the rubber with wood; that helped, but still left a nasty looking edge. I ordered and tried a razor saw but that didn’t work very well either. I was getting pretty stuck.

I started asking my friends at work about it. First response: “Aren’t you fixing a trim press right now that’s designed pretty much exactly for that?” …I probably should have thought of that. Anyway I was, and it's the perfect tool for this!

I started asking my friends at work about it. First response: “Aren’t you fixing a trim press right now that’s designed pretty much exactly for that?” …I probably should have thought of that. Anyway I was, and it's the perfect tool for this!